Hardwood Floors

Hardwood vs Softwood

Choosing the right material is one of the key points in your remodeling process. When it comes to wood, we already know about its versatility and the endless possibilities we can create with it, making our design dreams come true easily. However, it is important to understand the properties and characteristics of Hardwood Flooring. Let's take a closer look at the differences between hardwood and softwood.

THE SEED MAKES THE DIFFERENCE: Contrary to popular belief, the difference between hardwood and softwood has less to do with the strength of the tree and more with the seed type and reproduction of the species.

Hardwood trees (like oak, maple, or walnut) are angiosperms, their seeds have some sort of covering: a fruit or a hard shell. They are also deciduous trees, which means that they shed all or most of their leaves annually.

Monocots, like palm trees or bamboo, are not considered hardwood even though they are, in fact, angiosperm plants.

Softwood trees (like pine, cedar, or cypress) are gymnosperms. The seed-filled corn falls to the ground and is spread by the wind to other trees. Softwood trees maintain their leaves throughout the year (evergreen).

GROWTH RATE RELATES WITH PRICE: Softwood trees grow quicker than most hardwoods, they can mature in ten to twenty years, whereas hardwood trees need from twenty-five to one hundred years to fully mature. This huge difference has an impact on pricing. Softwoods are faster to harvest, more "available" and in fact, affordable.

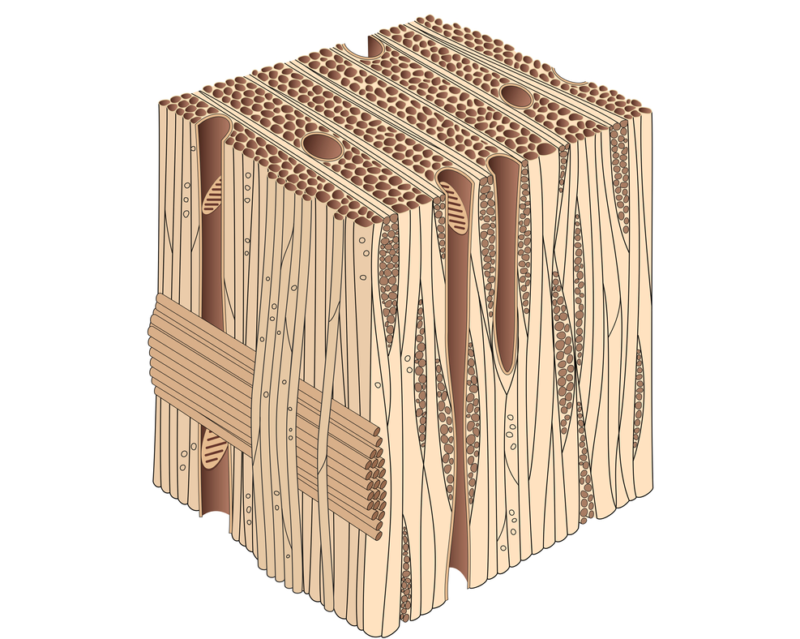

CELL STRUCTURE: THE KEY TO DENSITY, STRENGTH, AND DURABILITY: One fundamental difference between hardwood and softwood is the cellular structure. Pores, in hardwoods, are the vessels that transport water and nutrients within the wood. In softwoods, tracheids transport water and produce sap.

Hardwoods' complex and condensed structure is the reason why these types of trees have higher density & strength.

Closer look at hardwood's cellular structure with pores.

Hardwood Flooring

Because of its warm and welcoming looks, fine hardwood flooring has been the foundation of residential living for centuries. Beauty and durability along with the fact that wood is a renewable resource adds to its attraction as a flooring material. Using hardwood from sustainable and renewable sources, will add the best modern techniques to the beauty of nature. Hardwood is easy to install and designed for stability, strength and long-lasting resistance to stains and scratches. And after years of use, these environmentally friendly floors can be removed and reused or recycled. Although hardwood floors cost more than some other types of flooring, but it will bring positive value addition to your property and in most cases last much longer than softer flooring materials like carpet.

Types of Hardwood Floors

Basically there are 2 types of wood flooring construction available, Solid Hardwood & Engineered Hardwood.

Solid Hardwood Floors

Solid Hardwood Floor, or solid wood flooring, is entirely made from genuine wood throughout its thickness, usually a robust hardwood like oak, maple, or walnut. This type of flooring is renowned for its durability, beauty and longevity. Due to its nature, it can be sanded and refinished multiple times.

Solid wood flooring usually features long planks and narrower boards, which helps minimize the potential for cupping and offers better stability as there is less room for movement. This style also reminisces of the traditional hardwood flooring looks in older homes.

Solid wood flooring is 100% hardwood milled from one piece of wood, solid wood floor boards are generally three-quarters of an inch (3/4") thick. Solid hardwood can be installed above or on grade, but you don’t want to install this type of wood below grade, since moisture makes it expand and contract. Hardwood is a natural material, solid hardwood reacts to changes in its environment, like moisture and extreme temperatures, which cause solid wood to shrink or expand. Remember if even part of the area you’re finishing is underground (like a walk-out basement) it is considered below grade. Hardwood flooring is not suited to install below grade level or in other areas where it may be exposed to moisture. All solid hardwood can be sanded and refinished many times over the years.

Engineered Hardwood Floors

Engineered Wood Floors are the perfect combination of natural beauty and advanced engineering techniques. They resemble their solid counterparts, but their construction features a thin top layer of hardwood, and a high-quality multilayer plywood core. The core is the key to their numerous benefits: the multi-layered construction adds integrity, ensures long-lasting performance and adds resistance to fluctuations in humidity and temperature.

Engineered Hardwoods are constructed and built up with multiple layers of cross grain that are bonded together. It consists of three to ten layers, called plies that are glued together. The upper layer is made of a real wood selected from various species. The lower layers are made of different types of wood and it could be natural wood or man-made wood like plywood. This multi-ply structure gives engineered wood superior stability, much greater than solid hardwood, which reduces shrinking and expanding when temperature and humidity change. The grains in each successive layer have a different orientation making the wood more stable and less prone to warping. Stability is the biggest advantage of an engineered hardwood over the solid wood floor, thus it could be installed Below, On or Above Ground Level.

Engineered hardwood same as solid wood is available in pre-finished or unfinished, and can be find in all known species used in hardwood flooring industries along with many different finishes such as urethane finish or Oil Finish.

Engineered wood floor depends on its construction and dimensions can be direct glue-down, nail, staple or floated. Some engineered woods are also available in click and lock systems. Floating engineered wood needs to be installed directly over an underlayment, like cork flooring underlayment.

Poor constructed engineered wood floors use substandard glues that may contain volatile organic compounds. These cheap wood floors will emit VOC’s for years. Engineered wood made from cheap glues or made with poor quality base layers is likely to unravel in the blink of an eye. It is also better to visit a physical store and get a first hand idea of the appearance and finish of a floor instead of relying on online pictures.

One of the most important fact we all need to consider while purchasing our new wood floor is that the plant has been taken, harvested, possessed, transported, sold or exported legally in any foreign country or the U.S. "Lacey Act" banning commerce in illegally sourced plants and their wood products. The following are "Lacey Act" plant violation:

- Theft of plants

- Taking plants from an officially protected area, such as park or reserve,

- Taking plants without, or contrary to, the required authorization

- Failure to pay appropriate royalties, taxes or fees associated with the plant's harvest, transport or commerce

- Laws governing export or trans-shipment such as a log-export ban

Let's be responsible and buy our hardwood floor and any other wood products from a reputable manufacturer and retailer. Carpet Floor & More, Inc. is proud to be the authorized hardwood dealer for most those reputable manufacturers.

For fine hardwood floors, hardwood design ideas and hardwood installation consultation, visit our Los Angeles floor covering showroom where we carry high-end commercial hardwood floors and residential hardwood floors with many choices and patterns to choose from. Bring the natural beauty to your home decor with our designer choice of the latest stylish wood flooring, from strip solid & engineered hardwood to wide planks, long lengths and long strips wood floor. Experience how design, technology and sustainability work inunison across our selective products.

Hardwood Flooring Installation in Los Angeles

Carpet Floor & More has been installing hardwood flooring in Los Angeles and North America since 1987 and completed numerous hardwood floor projects with 100% satisfaction. Carpet Floor & More also sells hardwood floors in Los Angeles and other parts of North America. Our installation services are available in many cities of USA and CANADA.

Basically there are 3 different ways of installing hardwood floors, Nail Down or Staple Down, Glue Down and Floating method of hardwood installation.

Nail-down or Staple-down Method

In this method of installation hardwood installer will attach each harwood strip or hardwood plank to the wooden subfloor (plywood sub-floor in most cases) using pneumatic nailing gun or pneumatic stapler by driving nails or staples through the hardwood. First row will be top nailing installation (using hardwood glue is also recommended while top nailing), then blind nailing soon after. In blind nailing, nails or staples will be shoot to the hardwood in about 45 degree angle at the top of the tounge where tounge is attached to the board. The cleat of nail or crown of staple will sink slightly beneath the surface of the hardwood and will not impede a tight fit when installing the next row of hardwood. 3/4" solid hardwoods are normally installed using nail down or staple down method. This method can be used for installing engineered hardwood to wood subfloor as well.

*Please note that solid hardwood flooring should only be installed on wooden subfloors when it is on or above grade.

Glue-down Method

In glue down hardwood installation, floor boards are glued to the sub-floor using a recommended adhesive. This method of hardwood installation is for engineered wood flooring and some 5/16" thick solid wood flooring and solid perquet floors. The recommended adhesive is spread on the subfloor (wooden subfloor or concrete subfloor) with the proper sized trowel to adhere the hardwood flooring to the subfloor. Engineered wood floors and parquets can be glued down. There are many types of adhesives on the market and they are relatively expensive.

*Please keep the newly installed hardwood from foot traffic for about 10 hours to allow proper adhesion.

Floating Method

In this type of installation, hardwood floor is not mechanically attached to any part of the subfloor, instead engineered hardwood floors are glued or clicked together and laid over a thin layer of underlayment. When the planks are not in click system a bead of recommended wood adhesive is applied in the groove of each plank to glue the planks together. The underlayment placed between the wood flooring and the subfloor to provide a cushion and moisture barrier, preventing moisture from seeping back up from the sub-floor into the hardwood for extending the life of the hardwood floor.

Only dimensionally stable hardwood can be floated, floating hardwood must have the right dimensions such as width, length, thickness and also the construction. Carpet Floor & More, Inc. will not use floating method of installation on many hardwood floors even if it is recommended by it's manufacturer or supplier, when the boards are not qualified under our descretion. With over 25 years experience, Carpet Floor & More beleives that only and only wide planks and long planks of engineered hardwood flooring will provide a successfull floating installation.

Some Facts about Expansion and Contraction of Hardwood

Wood is hygroscopic material and, it will absorb or release moisture until in equilibrium of its surroundings.

*Gaps may occur due to change in seasons and/or changes in humidity.

*Wood will not swell or shrink equally; this may cause gaps in some areas of the floor and not in others.

*Gaps may be more excessive around vents or above the home’s heating system.

*Excessive moisture may cause cupping of a wood floor, although a small amount of cupping can be accepted as normal, especially in wider widths.

*Plank floors (3”-8” width) will expand and contract to greater degrees than strip flooring (1 ½”-2 ¼ “).

*Some species of wood may expand and contract more or less depending on the “stability” of the wood.

*All species of wood differ in stability characteristics and hardness. The Janka Scale is a measurement to determine the hardness of woods.

*With the normal expansion and contraction of wood, over time squeaks may occur from the nails and staples slowly becoming loose, however, most squeaks come from loose sub-floors rather than the c

In new installations, Carpet Floor & More takes as many steps as possible to secure the existing sub-floor to prepare it for a good installation; however in existing floors, squeaks may be difficult or not possible to fix.

Hardwood Flooring Brands

We carry a large variety of hardwood floors in Los Angeles; some of high quality hardwood floor brands are made by well known hardwood flooring suppliers and hardwood floor manufactures are: Anderson, Armstrong Hardwood, Bruce Hardwood, Carlisle Wide Plank Floors, Owens Planks & Owens Flooring by Colonial Craft, California Classics, Columbia Hardwood, Du Chateau Floors, Gemwood, Ernest Hemingway, Indus Parquet, Junckers Hardwood, Mannington, Mirage Hardwood Flooring, Mohawk Hardwood, Mullican Flooring, Navarre Wood Floors, Oasis, Oshkosh, Provenza, Shaw Hardwood Floors, Urban Floor, Virginia Vintage and ...